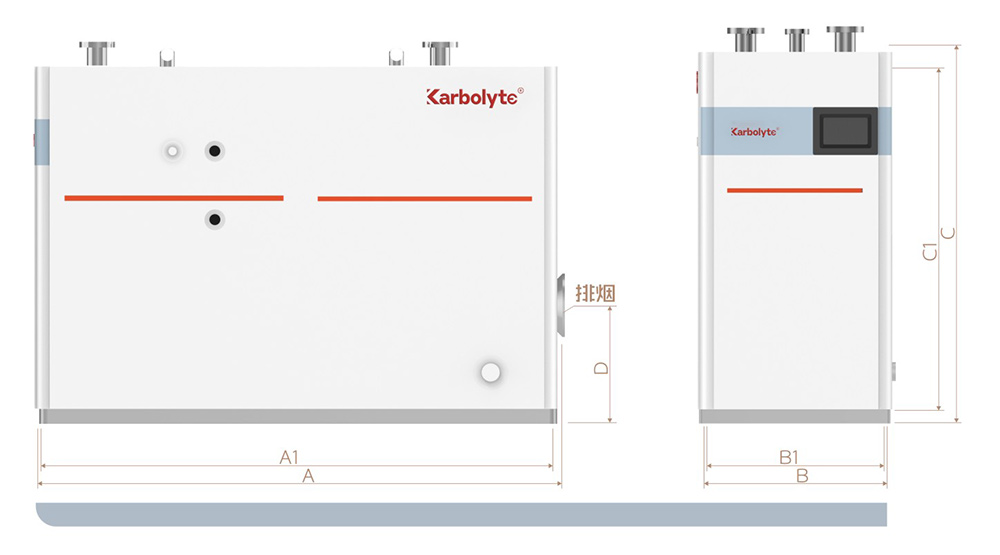

Ultra low nitrogen vacuum hot water unit

350kw-7000kw

Low noise

Adopting silent fans and proportional combustion to reduce noise to below 65dB

Ultra low nitrogen

Introduce the world's most advanced fully premixed large-scale flat combustion technology to reduce nitrogen oxide (NOx) emissions below 15mg/m.

High efficiency

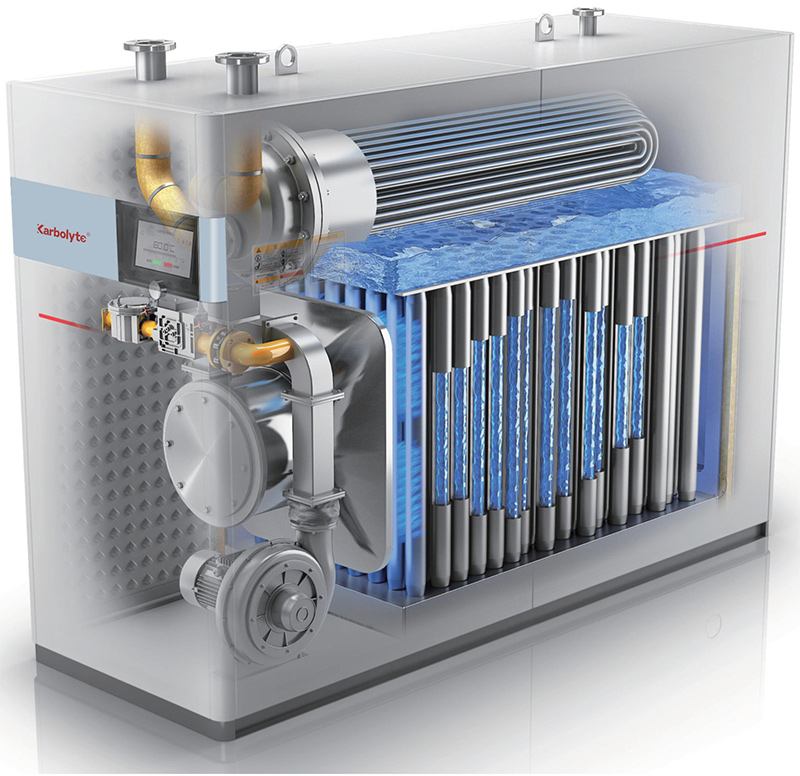

The forced air supply fully premixed ultra-low nitrogen (NOx) large-scale flat combustion technology, combined with tube bundle water-cooled furnace body and secondary condensation recovery technology, achieves a thermal efficiency of up to 104%.

Quick start

Adopting a high-efficiency tube bundle water-cooled furnace body structure, the amount of heat medium is low, and hot water can be produced within 5 minutes of startup. The preheating load is low, saving operating costs.

Low pressure of flowing gas

To meet the current situation of low gas flow pressure in some cities in China, the entire series of boilers can achieve high-efficiency and ultra-low nitrogen operation under 2Kpa pressure.

Intelligent control

Touch screen display, virtual buttons, self diagnosis of faults, fully automatic operation, and remote control through human-machine dialogue.

The Karbolyte hot water unit adopts revolutionary large-scale flat combustion ultra-low nitrogen tube bundle water-cooled furnace technology. The flat combustion is composed of tens of thousands of micro flames, and combined with the self-developed most advanced through flow unique tube bundle furnace structure, the flame cooling is rapid, greatly suppressing the generation of nitrogen oxides (NOx), and reducing the emission of nitrogen oxides (NOx) to below 15mg/m3.

The Karbolyte hot water unit adopts revolutionary large-scale flat combustion ultra-low nitrogen tube bundle water-cooled furnace technology. The flat combustion is composed of tens of thousands of micro flames, and combined with the self-developed most advanced through flow unique tube bundle furnace structure, the flame cooling is rapid, greatly suppressing the generation of nitrogen oxides (NOx), and reducing the emission of nitrogen oxides (NOx) to below 15mg/m3.