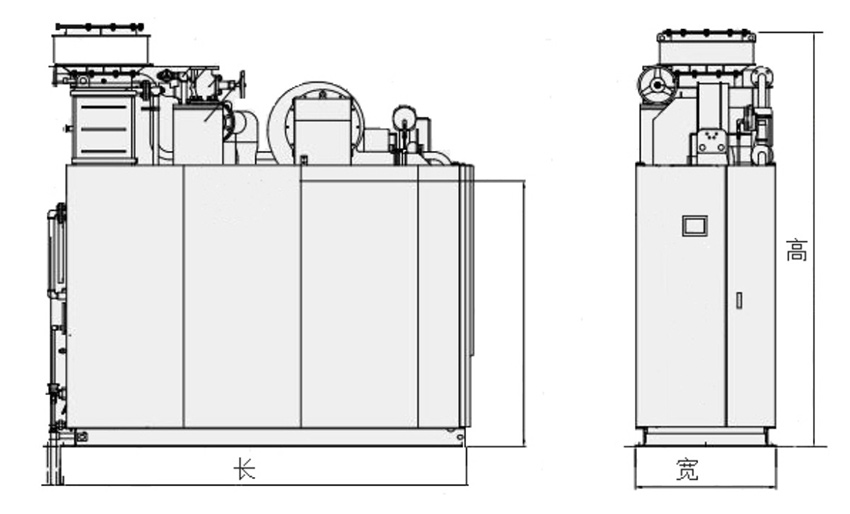

Inspection free ultra-low nitrogen steam engine

600kg/h-2000kg/h

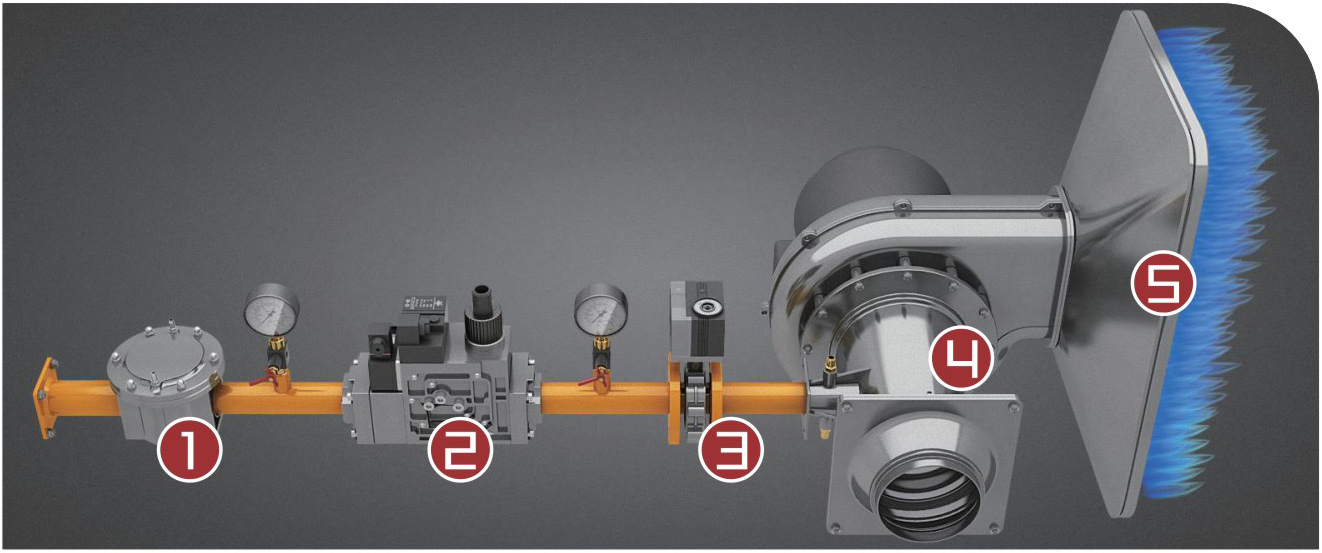

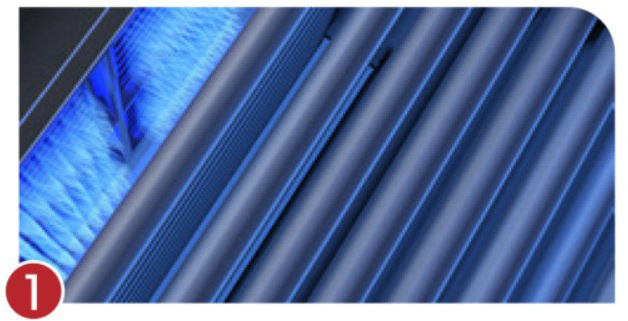

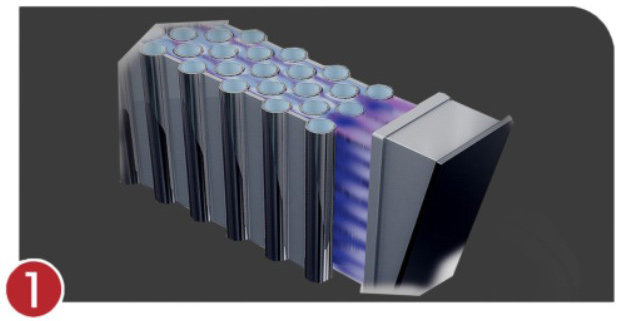

Karbolyte steam engine adopts the revolutionary large flat combustion low nitrogen tube bundle water-cooled furnace body technology. The flat combustion is composed of tens of thousands of micro flames. In combination with Karbolyte's unique tubular tube bundle furnace body structure, the flame cooling is rapid and greatly inhibits the generation of nitrogen oxides (NOx), reducing the emission of nitrogen oxides (NOx) to below 30mg/m3. The hot rolled tube bundle furnace body structure has high heat transfer coefficient and low water retention. The boiler can be started for 1-3 minutes, and the heat loss during purging is reduced by 20%. There is no preheating load loss, and the operating efficiency is up to more than 98%.

The working noise is below 70dB, truly achieving ultra-low nitrogen, low noise, and high efficiency work.